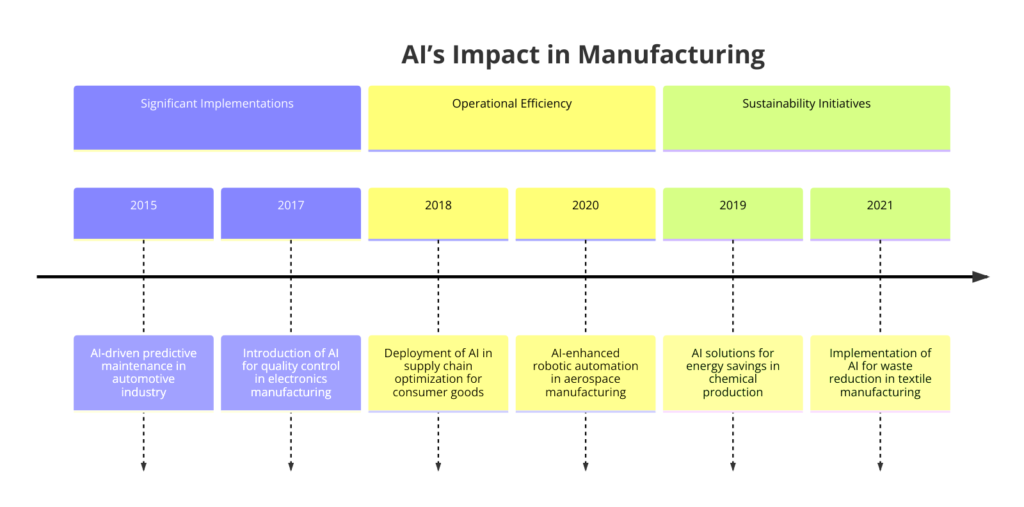

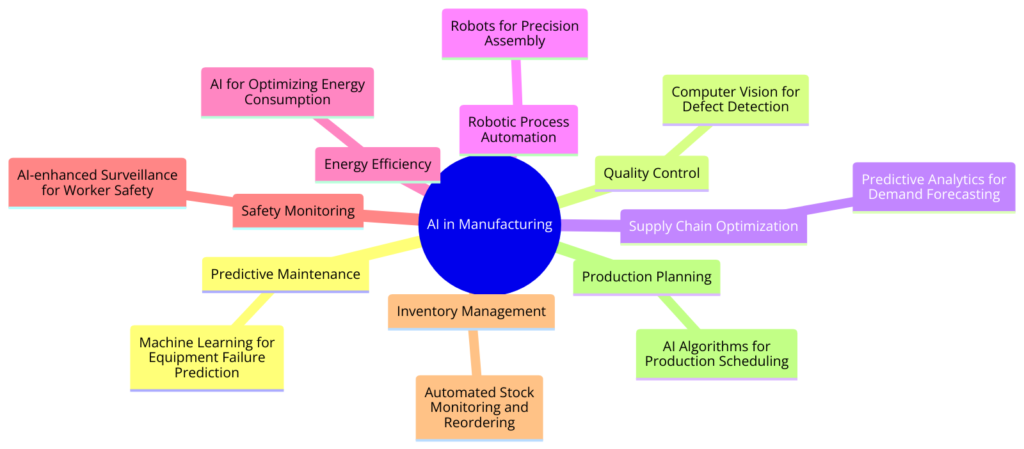

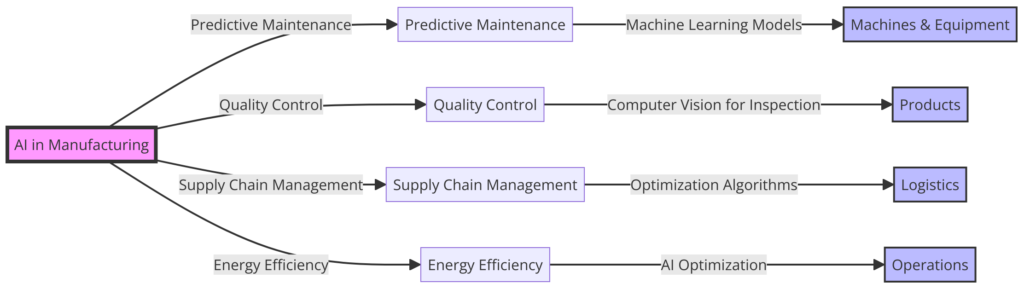

AI in Manufacturing is about automating routine tasks and leveraging AI to make manufacturing processes more efficient, adaptive, and intelligent. AI-driven optimization encompasses various applications, from predictive maintenance and quality control to production scheduling and energy consumption reduction, each aimed at enhancing operational efficiency and productivity. In this section, we explore how AI is used to optimize manufacturing operations, including case studies that illustrate the tangible benefits of these technologies.

1. AI in Production Optimization

Predictive Maintenance

One of the most impactful applications of AI in manufacturing is predictive maintenance. Traditional maintenance strategies rely on scheduled checks or reactively responding to equipment failure.

In contrast, predictive maintenance utilizes AI algorithms to analyze data from sensors embedded in machinery to predict equipment failures before they occur.

Machine learning models process historical and real-time data to identify patterns or anomalies that precede a failure, allowing maintenance to be conducted just in time to prevent downtime.

This approach reduces unplanned downtime, extends equipment lifespans, and optimizes maintenance resources.

A case study highlighting the efficacy of predictive maintenance is that of a major automotive manufacturer.

By implementing AI-driven predictive maintenance, the company reported a 30% reduction in maintenance costs and a significant decrease in downtime, increasing overall production efficiency.

AI-Driven Production Scheduling

Another key area where AI contributes significantly to production optimization is scheduling.

AI algorithms can process complex data sets to optimize production schedules, considering constraints such as machine availability, labor skills, and supply chain logistics.

This dynamic scheduling capability enables manufacturers to adapt to changes in demand, resource availability, or production capacity in real-time, ensuring that production always aligns with business goals.

An example of AI in action for production scheduling can be seen in the electronics manufacturing sector.

A leading electronics manufacturer used AI to overhaul its production scheduling, resulting in a 20% increase in production capacity without additional capital expenditure.

The AI system identified bottlenecks and optimized workflows, demonstrating how intelligent algorithms can significantly enhance production efficiency.

Case Studies of AI-Driven Optimization in Factories

Several real-world case studies underscore AI’s transformative impact on manufacturing operations.

For instance, a textile manufacturing company implemented AI to optimize energy consumption.

By analyzing data from various sensors and predicting energy needs, the AI system could adjust machinery operation times and reduce energy consumption by 15%, leading to substantial cost savings.

Another case study involves a food and beverage company that utilized AI to optimize its supply chain and production planning.

The AI system forecasted demand more accurately, optimized inventory levels, and improved production planning.

This led to reduced waste, lower storage costs, and a more agile response to market changes.

AI’s role in production optimization is a testament to the technology’s potential to revolutionize manufacturing.

Through predictive maintenance, AI-driven production scheduling, and other applications, AI enables factories to become more efficient, flexible, and resilient.

The case studies highlighted in this section illustrate the feasibility of integrating AI into manufacturing operations and the tangible benefits of doing so.

As AI technology continues to evolve and mature, its impact on production optimization is expected to grow, paving the way for more innovative, efficient manufacturing processes.

2. AI in Quality Control

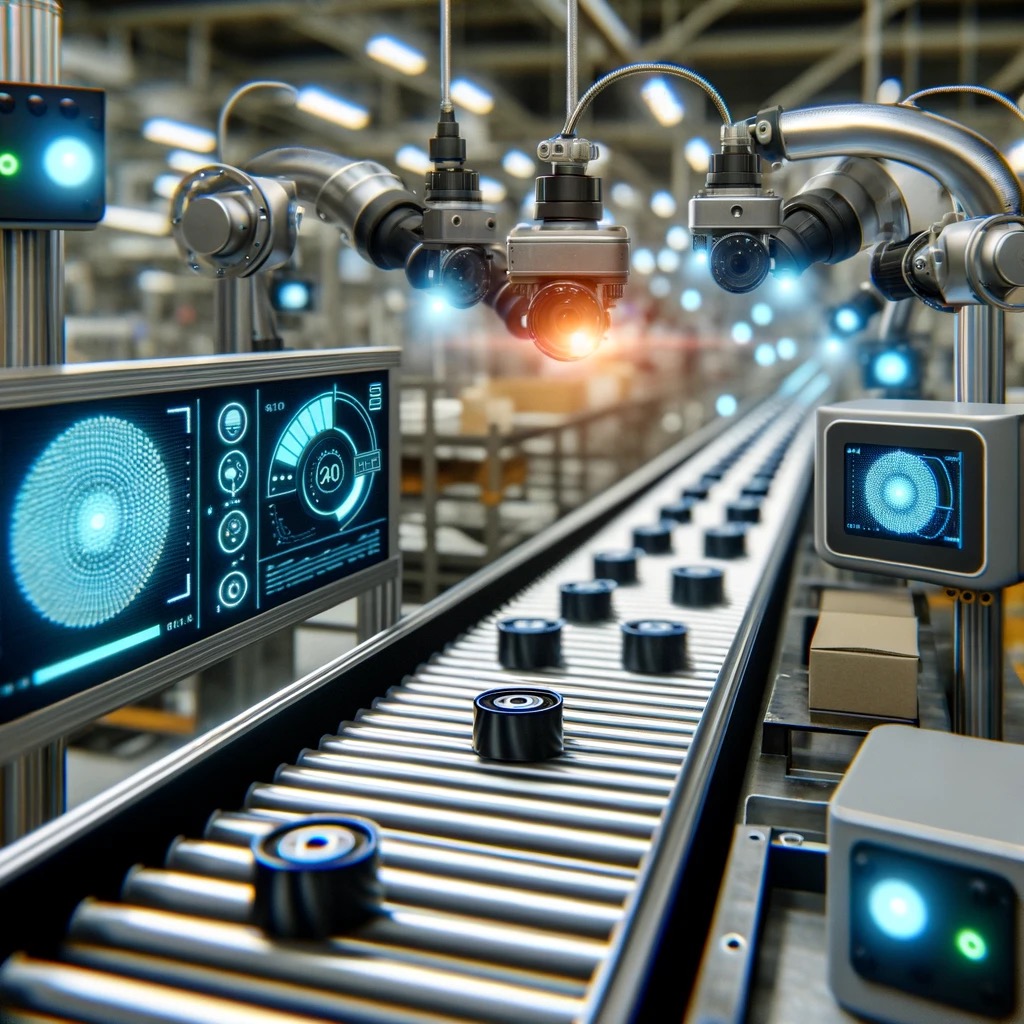

Integrating Artificial Intelligence (AI) into quality control processes marks a significant leap forward in manufacturing, introducing levels of precision, efficiency, and automation previously unattainable.

This transformative approach leverages machine learning, computer vision, and advanced analytics to automate the inspection process, enhance defect detection, and ensure compliance with quality standards.

The ability of AI to analyze vast amounts of data in real time enables manufacturers to maintain and significantly improve product quality.

Automating Quality Inspection

Traditional quality inspection methods are often labor-intensive and subject to human error, leading to inconsistencies in product quality.

AI transforms this process through computer vision and machine learning algorithms that can analyze images or sensor data to detect anomalies, defects, or deviations from the norm with unparalleled accuracy and speed.

These AI systems are trained on vast datasets of product images or specifications, allowing them to recognize a wide range of issues, from minor cosmetic flaws to critical functional defects.

The automation of quality inspection not only enhances accuracy but also significantly speeds up the inspection process, enabling real-time quality control.

This rapid feedback loop allows immediate corrective actions, reducing waste and rework. Furthermore, AI systems can adapt and improve over time, learning from new data to recognize defects more accurately.

Examples of AI Applications in Quality Control

One illustrative example of AI in quality control is in the automotive industry, where precision and reliability are paramount.

An automotive manufacturer implemented an AI-based visual inspection system to detect defects in car paint finishes.

The system, trained on thousands of images of car surfaces, could identify and classify defects with over 95% accuracy, significantly reducing the manual effort required for inspection and ensuring that only cars meeting the highest quality standards reached customers.

In electronics, AI-driven quality control plays a crucial role in inspecting circuit boards. Traditional inspection methods might miss minor defects, leading to electronic device failures.

An AI-powered system can scrutinize soldering joints, component placements, and other critical aspects of a circuit board with extraordinary detail, ensuring that every product meets stringent quality criteria.

Impact of AI on Product Quality

The deployment of AI in quality control processes profoundly impacts product quality.

By enabling early detection of defects and facilitating real-time quality assurance, AI helps manufacturers consistently maintain high standards.

This minimizes the risk of defective products reaching the market and enhances brand reputation and customer satisfaction.

Moreover, the data collected by AI systems during the inspection process provides valuable insights into the root causes of defects, enabling manufacturers to improve their processes and prevent future issues.

This continuous improvement cycle, driven by AI, leads to higher-quality products and more efficient manufacturing processes.

AI’s application in quality control transforms the manufacturing industry, setting new standards for precision, efficiency, and automation.

The ability of AI to automate inspection processes, enhance defect detection, and ensure compliance with quality standards is not just improving product quality but also driving operational efficiency.

As AI technology continues to advance, its role in quality control is expected to become even more pivotal, further enhancing the ability of manufacturers to deliver products of the highest quality.

The examples provided illustrate the tangible benefits of AI in quality control, underscoring its significant impact on the manufacturing sector.

3. AI in Supply Chain Management

Artificial Intelligence (AI) is revolutionizing supply chain management in the manufacturing sector by introducing unprecedented efficiency, accuracy, and resilience levels.

By harnessing the power of AI, manufacturers can anticipate market changes, optimize inventory levels, enhance logistics, and ensure a seamless flow of goods from suppliers to customers.

Enhancing Supply Chain Efficiency with AI

Through predictive analytics and machine learning, AI technologies empower manufacturers to forecast demand with greater precision, optimizing production planning and inventory management.

This predictive capability is crucial for maintaining the right balance between supply and demand, reducing the risk of overstocking or stockouts, and minimizing waste.

Furthermore, AI-driven tools can identify patterns and insights from historical supply chain data, enabling companies to streamline operations, reduce costs, and improve overall supply chain performance.

AI also plays a pivotal role in logistics optimization, from route planning to warehouse management.

By analyzing vast amounts of data, AI algorithms can determine the most efficient transportation routes, taking into account factors such as traffic conditions, weather, and fuel costs.

In warehouses, AI-powered robots and automated systems enhance the speed and accuracy of picking and packing processes, reducing lead times and labor costs.

Innovations in AI for Resilient and Adaptive Supply Chain Systems

The global nature of modern supply chains exposes them to a range of disruptions, from natural disasters to geopolitical tensions.

AI technologies enable developing more resilient and adaptive supply chain systems capable of withstanding and quickly recovering from such disruptions.

For instance, AI-driven scenario planning tools allow companies to simulate various supply chain disruptions and develop effective mitigation strategies, ensuring business continuity in adverse conditions.

Moreover, AI facilitates real-time supply chain visibility, allowing companies to monitor the status of goods as they move through the supply chain.

This real-time tracking, combined with AI’s predictive analytics, enables companies to anticipate and respond to potential delays or disruptions, adjusting their strategies to ensure timely delivery of goods.

Case Studies: AI in Action within Supply Chains

One notable case study involves a leading global retailer implementing an AI-powered demand forecasting system.

By analyzing data from various sources, including market trends, consumer behavior, and weather forecasts, the system improved demand prediction accuracy by over 50%.

This enhanced forecasting enabled more efficient inventory management, reducing overstock and stockouts and significantly cutting down on wasted resources.

Another example is a logistics company that used AI to optimize its delivery routes.

By leveraging machine learning algorithms, the company dynamically adjusted routes based on real-time data, such as traffic and weather conditions, reducing delivery times by 20% and fuel consumption by a significant amount.

Integrating AI into supply chain management transforms the manufacturing industry, making supply chains more efficient, resilient, and adaptive.

Through predictive analytics, machine learning, and other AI technologies, manufacturers can achieve greater accuracy in demand forecasting, optimize inventory and logistics, and enhance the overall performance of their supply chains.

As AI continues to evolve, its potential to improve supply chain management is immense, offering opportunities for innovation and competitive advantage.

The case studies underscore AI’s tangible benefits in supply chains, highlighting its critical role in the modern manufacturing landscape.

4. AI in Robotics and Automation

The fusion of Artificial Intelligence (AI) with robotics and automation is redefining the manufacturing landscape, ushering in an era of increased efficiency, precision, and safety.

AI-enhanced robotics can perform complex tasks, from assembly and welding to sorting and packaging, with a level of sophistication and adaptability that far exceeds traditional automated systems.

Integration of AI with Robotics for Automated Manufacturing Processes

Integrating AI into robotics has led to the development of intelligent robots that can learn, adapt, and make decisions in real-time.

These robots are equipped with sensors and machine-learning algorithms that enable them to understand their environment and perform exact tasks.

For example, AI-powered robotic arms can adjust their actions based on the shape, size, and orientation of objects, enabling them to handle a wide variety of products without the need for manual reprogramming.

Moreover, AI enables robots to work collaboratively with humans, creating a more flexible and efficient manufacturing environment.

These collaborative robots, or cobots, are designed to operate alongside human workers, assisting with tasks that require precision or are ergonomically challenging.

Cobots are equipped with safety features and sensors that allow them to detect the presence of humans and adjust their movements to avoid collisions, enhancing worker safety.

The Impact of AI-Powered Robots on Production Lines

The deployment of AI-powered robots on production lines has significantly increased productivity and operational efficiency.

These robots can operate 24/7, performing repetitive tasks consistently and accurately, freeing human workers to focus on more complex and creative tasks.

This shift boosts production capacity and reduces the likelihood of errors and defects, improving product quality.

Furthermore, AI-powered robots can quickly adapt to changes in production requirements, enabling manufacturers to respond more rapidly to market demands.

This flexibility is precious in industries such as consumer electronics, where product designs and specifications frequently change.

Enhancing Worker Safety with AI Robotics

One of AI’s most significant benefits in robotics and automation is enhancing worker safety. AI-powered robots can perform hazardous tasks, such as handling toxic materials or operating in extreme temperatures, reducing the risk of injury to human workers.

Additionally, the precision and reliability of AI robots minimize the chances of accidents caused by human error or mechanical failure.

Implementing Robots in manufacturing also contributes to a safer work environment by reducing the physical strain on workers. Robots can take over physically demanding tasks, such as lifting heavy objects or performing repetitive motions, which can lead to musculoskeletal disorders.

Integrating AI with robotics and automation propels the manufacturing industry towards a future characterized by increased efficiency, flexibility, and safety.

AI-powered robots transform production lines, enabling manufacturers to achieve higher productivity and product quality while protecting human workers.

As AI technology advances, the potential for further innovation in robotics and automation is vast, promising even more significant improvements in manufacturing processes.

The impact of AI-powered robots on the industry highlights the importance of embracing these technologies to maintain competitiveness in the global market.

5. Challenges and Ethical Considerations

Integrating Artificial Intelligence (AI) into manufacturing, while bringing numerous benefits, also presents significant challenges and ethical considerations.

As manufacturers navigate the transition towards more automated and AI-driven processes, they face issues related to workforce displacement, data security, algorithmic bias, and ethical deployment of AI technologies.

Workforce Displacement and Reskilling

One of the most pressing concerns with adopting AI in manufacturing is the potential displacement of workers due to automation.

As AI-powered robots and systems take on tasks previously performed by humans, job loss in specific roles is likely, particularly those involving repetitive or manual tasks.

However, this challenge also presents an opportunity for workforce transformation and reskilling.

Manufacturers can invest in training programs to equip their employees with the skills needed in an AI-driven industry, such as data analysis, machine learning, and robotics maintenance.

This approach mitigates the impact of displacement and enhances the workforce’s ability to contribute to more innovative and high-value tasks.

Data Security and Privacy

The deployment of AI in manufacturing relies heavily on data, raising concerns about data security and privacy.

Manufacturers must protect sensitive information, including proprietary production processes, employee data, and customer information.

Implementing robust cybersecurity measures and adhering to data protection regulations are crucial to addressing these concerns.

Additionally, transparency about data usage and ensuring that data collection practices respect privacy rights are essential to maintaining trust among stakeholders.

Algorithmic Bias and Fairness

Algorithmic bias is another ethical concern in using AI in manufacturing. If AI systems are trained on biased data sets, they may perpetuate or exacerbate these biases, leading to unfair outcomes.

For example, an AI-driven hiring system might discriminate against specific candidates if the training data reflects historical biases.

Manufacturers must be vigilant in auditing and testing their AI systems for bias and take steps to ensure that AI applications promote fairness and inclusivity.

Ethical Deployment of AI Technologies

The ethical deployment of AI technologies in manufacturing extends beyond technical considerations to encompass the broader impact on society and the environment.

Manufacturers must consider the moral implications of their AI strategies, including the sustainability of AI-driven processes and the social impact of increased automation.

Engaging with stakeholders, including employees, customers, and the wider community, can help identify ethical concerns and guide the responsible use of AI.

The challenges and ethical considerations associated with integrating AI in manufacturing underscore the importance of a balanced and thoughtful approach to adopting these technologies.

Addressing workforce displacement through reskilling initiatives, ensuring data security and privacy, mitigating algorithmic bias, and considering the broader ethical implications of AI deployment are critical steps in realizing the benefits of AI while minimizing its potential drawbacks.

As the manufacturing industry continues to evolve with the advancement of AI, embracing these challenges as opportunities for growth and improvement will be vital to achieving sustainable and ethical innovation.

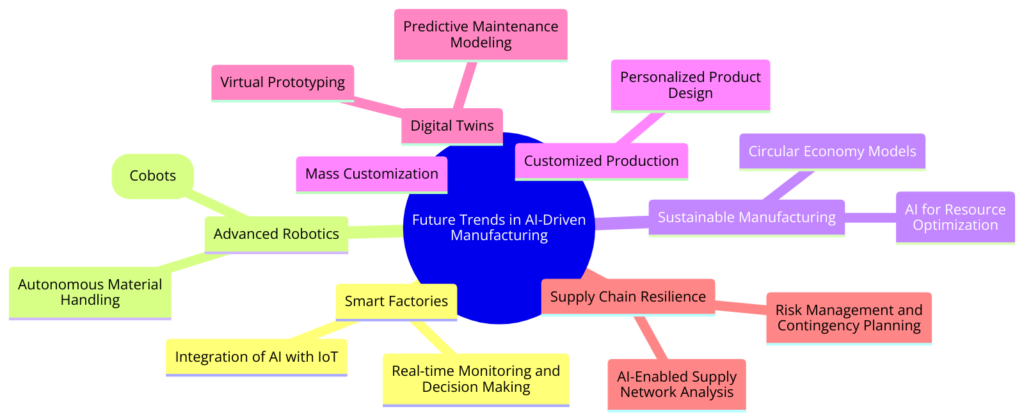

6. The Future of AI in Manufacturing

The future of AI in manufacturing is poised to revolutionize the industry further, driving innovations that promise to enhance efficiency, productivity, and sustainability.

As AI technologies continue to evolve, their applications in manufacturing will expand, leading to more intelligent, connected, and adaptable production processes.

Predictions for AI Advancements in Manufacturing

- Customization and Personalization through AI: AI will enable greater customization and personalization of products at scale, catering to individual customer preferences without significantly impacting production efficiency. This shift towards more personalized manufacturing could transform consumer expectations and market dynamics.

- Sustainable Manufacturing Practices: AI-driven optimizations will increasingly focus on sustainability, enabling manufacturers to reduce waste, minimize energy consumption, and lower their carbon footprint. AI could play a pivotal role in achieving environmentally sustainable manufacturing practices.

- Enhanced Supply Chain Resilience: AI will further enhance supply chain resilience, offering more sophisticated tools for risk management and disruption recovery. Predictive analytics and real-time monitoring will enable manufacturers to anticipate and mitigate the impact of supply chain disruptions more effectively.

Emerging Trends in AI-Driven Manufacturing

- Quantum Computing in Manufacturing: The potential integration of quantum computing with AI could lead to breakthroughs in solving complex optimization problems, such as material science research, logistics planning, and production scheduling.

- AI Ethics and Governance: As AI becomes more integral to manufacturing, there will be a growing focus on establishing ethical guidelines and governance frameworks to ensure responsible AI use. This includes addressing data privacy, security, and the societal impact of automation.

- Collaborative AI Ecosystems: The future will likely develop more collaborative AI ecosystems, where manufacturers, technology providers, and academic institutions work together to innovate and solve industry challenges. These collaborations could accelerate the pace of AI adoption and innovation in manufacturing.

The future of AI in manufacturing is bright, with advancements in technology poised to introduce new levels of efficiency, customization, and sustainability.

Integrating AI with other emerging technologies promises to transform the industry further, making manufacturing processes more innovative, flexible, and environmentally friendly.

However, realizing this future will require addressing the ethical and practical challenges of AI integration, ensuring that advancements in AI contribute positively to the industry and society.

As manufacturers navigate these challenges, AI’s continuous innovation and responsible integration will be crucial for achieving long-term success and competitiveness in the global market.

7. Conclusion

The exploration of AI’s role in manufacturing across various dimensions—from production optimization and quality control to supply chain management, robotics, automation, and addressing challenges and ethical considerations—underscores artificial intelligence’s profound impact and potential in transforming the industry.

As we have discussed, AI technologies offer significant opportunities to enhance efficiency, quality, innovation, and sustainability within manufacturing processes while presenting challenges that require careful management and ethical consideration.

Recap of AI’s Role in Enhancing Efficiency, Quality, and Innovation

AI’s transformative power in manufacturing is evident in its ability to optimize production processes, improve product quality through advanced quality control measures, and streamline supply chain operations for greater efficiency and resilience.

The integration of AI with robotics and automation technologies has not only increased production capabilities but also made manufacturing environments safer for workers.

These advancements have facilitated a shift towards more data-driven, flexible, and efficient manufacturing practices that adapt to changing market demands and technological advancements.

However, the journey towards fully realizing AI’s benefits in manufacturing also involves navigating the complexities of workforce displacement, data security, algorithmic bias, and the ethical deployment of AI technologies.

Addressing these challenges is critical to ensuring that the integration of AI into manufacturing contributes positively to the industry and society at large.

Encouraging Continuous Innovation and Responsible AI Integration

The potential marks the future of AI in manufacturing for further advancements that promise to redefine the industry.

Emerging trends, such as integrating AI with the Internet of Things (IoT), digital twins, and quantum computing, point towards an era of even more innovative manufacturing processes.

These advancements underscore the importance of continuous innovation and the responsible integration of AI technologies.

Manufacturers and stakeholders must prioritize the development of skills and knowledge to keep pace with technological advancements, ensuring that the workforce is prepared for the future of manufacturing.

Additionally, establishing ethical guidelines and governance frameworks for AI use will be crucial in addressing the societal implications of increased automation and data usage.

In conclusion, the role of AI in manufacturing is multifaceted, offering opportunities to drive significant improvements in efficiency, quality, and innovation.

As the industry continues to evolve with these technological advancements, the emphasis on ethical considerations and responsible AI integration becomes increasingly important.

By embracing AI technologies and addressing the associated challenges head-on, the manufacturing industry can continue to innovate and thrive, ensuring competitiveness and sustainability in a rapidly changing world.

Encouraging continuous innovation and responsible integration of AI will be vital in shaping a future where technology and human ingenuity converge to create more innovative, efficient, and sustainable manufacturing processes.

FAQ & Answers

1. How is AI used in manufacturing?

AI is utilized to optimize production processes, improve quality control, manage supply chains efficiently, and integrate robotics for automation.

2. What are the challenges of implementing AI in manufacturing?

Challenges include adapting workforce skills, ensuring data privacy, and managing the ethical implications of automation on employment.

Quizzes

Quiz 1: “AI in Manufacturing” – Match AI technologies to their manufacturing applications.

For a quiz on “AI in Manufacturing,” we’ll match various AI technologies with their applications within the manufacturing sector. This will help to understand how AI is transforming manufacturing through automation, optimization, and predictive analytics.

AI Technologies:

- Machine Learning (ML)

- Deep Learning (DL)

- Natural Language Processing (NLP)

- Computer Vision

- Reinforcement Learning

- Robotics

- Predictive Analytics

Manufacturing Applications:

A) Quality Control: Automating inspection and defect detection processes to ensure product quality meets high standards.

B) Predictive Maintenance: Using data analysis tools to predict equipment failures before they happen, reducing downtime and maintenance costs.

C) Supply Chain Optimization: Enhancing supply chain efficiency through demand forecasting, inventory management, and logistics optimization.

D) Human-Robot Collaboration: Facilitating safe and efficient interactions between human workers and robots on the production floor.

E) Process Optimization: Improving manufacturing processes through simulation, analysis, and optimization of production parameters.

F) Voice-Activated Control: Enabling hands-free operation of machinery and equipment through voice commands.

G) Visual Inspection and Measurement: Leveraging image recognition and analysis for quality assurance and dimensional accuracy.

Matches:

- Machine Learning (ML): B) Predictive Maintenance – ML algorithms analyze historical data to predict future failures and maintenance needs.

- Deep Learning (DL): G) Visual Inspection and Measurement – DL, especially convolutional neural networks, is highly effective in image-based quality control applications.

- Natural Language Processing (NLP): F) Voice-Activated Control – NLP technologies allow for the development of systems that can understand and act on human voice commands.

- Computer Vision: A) Quality Control – Computer vision systems are used extensively for automated inspection and defect detection in manufacturing processes.

- Reinforcement Learning: E) Process Optimization – Reinforcement learning can optimize manufacturing processes by learning from simulations and real-world operations to improve efficiency.

- Robotics: D) Human-Robot Collaboration – Advanced robotics, combined with AI, enables robots to work alongside humans safely and effectively, enhancing productivity and flexibility.

- Predictive Analytics: C) Supply Chain Optimization – Predictive analytics tools use AI to forecast demand, optimize inventory levels, and improve logistics planning.

These matches illustrate the broad range of applications for AI technologies within the manufacturing industry, driving improvements in efficiency, quality, and operational flexibility.

Quiz 2: “Innovations in Manufacturing” – A quiz on recent AI innovations in the manufacturing sector.

For a quiz on recent AI innovations in the manufacturing sector, we’ll focus on new developments and applications of AI that have emerged as significant trends. These questions will highlight how AI technologies are being applied innovatively to solve complex problems, improve efficiency, and create new capabilities within the manufacturing industry.

Question 1: AI-Enhanced Predictive Maintenance

What is a primary benefit of AI-enhanced predictive maintenance in manufacturing?

A) It allows for longer working hours for machinery.

B) It reduces the need for human supervision of machines.

C) It significantly reduces unplanned downtime and maintenance costs.

D) It increases the speed of manufacturing processes.

Question 2: Digital Twins

How do AI-powered digital twins benefit manufacturing processes?

A) By replacing physical prototypes with digital ones.

B) By providing real-time monitoring and simulation capabilities that help in optimizing manufacturing operations and product development.

C) By completely automating the manufacturing process, eliminating the need for human workers.

D) By enforcing stricter cybersecurity measures.

Question 3: Generative Design

What is the role of AI in generative design within the manufacturing sector?

A) To automate the marketing of manufactured products.

B) To explore a vast space of design alternatives based on specified constraints and objectives, optimizing for performance, materials, and cost.

C) To generate legal documentation for new designs automatically.

D) To replicate competitor designs for analysis.

Question 4: Collaborative Robots (Cobots)

Which of the following best describes the use of AI in collaborative robots (cobots) in manufacturing?

A) Cobots are designed to operate independently from humans and make their own decisions.

B) Cobots use AI to safely interact and collaborate with human workers, enhancing productivity and flexibility.

C) Cobots primarily use AI to replace human workers in all manufacturing tasks.

D) Cobots are solely used for heavy lifting and tasks that are dangerous to human workers.

Question 5: Machine Vision for Quality Control

How does machine vision, powered by AI, innovate quality control in manufacturing?

A) It eliminates the need for any quality control measures.

B) It uses advanced imaging and analysis to detect defects and anomalies at speeds and accuracies beyond human capability.

C) It relies on human inspectors to make final decisions.

D) It focuses exclusively on packaging quality.

Question 6: AI in Supply Chain Optimization

What is a key way AI contributes to supply chain optimization in manufacturing?

A) By predicting future trends in fashion and product design.

B) By ensuring that all employees adhere to safety protocols.

C) By dynamically adjusting production schedules and logistics based on demand forecasts, inventory levels, and supplier performance.

D) By manually tracking shipments.

Question 7: AI for Environmental Sustainability

How is AI being used to promote environmental sustainability in manufacturing?

A) By reducing the reliance on digital technology.

B) By optimizing energy use and reducing waste in manufacturing processes through smart analytics and process adjustments.

C) By lobbying for environmental laws.

D) By focusing solely on increasing production outputs.

These questions and answers aim to capture some of the most impactful ways AI is shaping the future of manufacturing, from enhancing operational efficiency to fostering innovation in product design and production processes.